SOPHIA ANTIPOLIS, France – February 22, 2023 │ The health and nutritional benefits boost the high demand for natural astaxanthin. The algae-based astaxanthin dominates the dietary market, but it presents a huge weakness: a fishy smell. Therefore, microbial astaxanthin takes advantage of the algae product’s flaw to consolidate its position in the dietary supplement market.

High demand for astaxanthin: king of antioxidant

Astaxanthin is the main carotenoid responsible for the pink-red pigmentation of fish and crustaceans. Nutritionally, astaxanthin is considered one of the most powerful antioxidants in nature because of its high ability to scavenge free radicals in the human body. Several studies have shown the beneficial biological properties of this powerful antioxidant, such as anti-aging, anti-inflammation, immuno-modulation, anticancer, lipid-lowering, and anti-diabetes effects (Hussein et al., 2006). Astaxanthin can even cross the blood-brain barrier and has great potential for preventing and treating neurological conditions such as Alzheimer’s and Parkinson’s diseases (Galasso et al., 2018). Since the human body cannot synthesize astaxanthin, the demand for it to benefit human health has been increasing every year. Astaxanthin is used not only in pharmaceuticals and nutraceuticals but also in food, beverages, and animal feed. According to Grand view research, the global astaxanthin market size was valued at $1,943 M in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 17.2% from 2023 to 2030.

Different sources of natural and synthetic astaxanthin

This bioactive compound can be obtained through extraction from natural sources or chemical synthesis. The latter, currently utilized by a handful of large chemical companies such as BASF and DSM, involves a multi-step transformation process from petrochemicals. This is presently the most cost-effective process (about 1,000 USD/kg), thus the synthetic astaxanthin has dominated over 95% of the feed market. However, the synthetic compound has significant differences in its structural and optical isomerism compared to the natural astaxanthin, and presents a bioactivity 20-30 times lower than its natural counterpart (Capelli et al., 2013). Moreover, only natural sources are permitted for food, pharmaceutical, and nutraceutical applications. Astaxanthin biosynthesis has been reported in several marine organisms, but the commercial natural astaxanthin is mainly from Haematococcus and Phaffia yeast. H. pluvialis, a green microalgae, accumulates high astaxanthin content of up to 3.8% of its dry weight basis under stress conditions such as high salinity, nitrogen deficiency, high temperature, and light (Ambati et al., 2014). Currently, astaxanthin produced from H. pluvialis is the main source for human consumption, costing 7,000 USD/kg. However, algae astaxanthins are not organoleptically attractive due to their fishy smell and taste. This is why the neutral-flavored astaxanthin AstaFerm produced from yeast and marketed by NextFerm has caught the attention of leading US dietary supplement brands.

NextFerm – producer of yeast-derivate food and pharmaceutical ingredients

NextFerm was founded in 2014 by former executives of Enzymotec, which developed fatty acids for food additives and baby food and was acquired by Frutarom in 2017. NextFerm develops specialized ingredients for food and pharmaceutical companies based on the control of yeast evolution. Its portfolio comprises five patent families published between 2018 and 2021. Of these, one has lapsed, and two pending patent applications relate to yeast-derived astaxanthin AstaFerm, while the two other patents describe a freeze-resistant baker’s yeast, which has been licensed to Lallemand. For marketing, their core products are ProteVin (yeast protein, launched in 2022) and AstaFerm, the microbial astaxanthin in question.

AstaFerm: Microbial astaxanthin with high stability, bioavailability, and neutral flavor

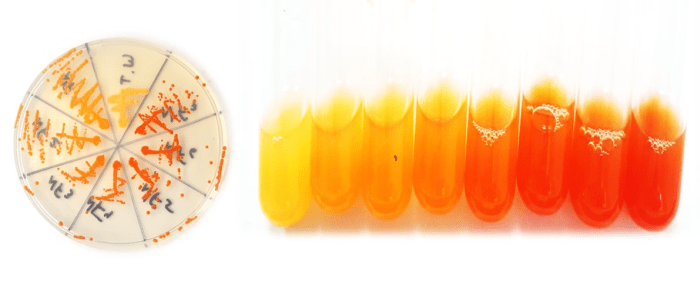

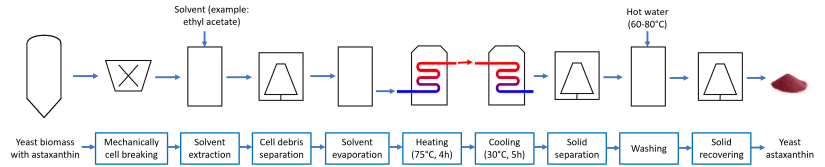

AstaFerm, branded by NextFerm, is a natural astaxanthin obtained through a fermentation process with an improved yeast strain and an optimized extraction. Firstly, the company developed the Phaffia rhodozyma (sexual form: Xanthophyllomyces dendrorhous) strains characterized by an over-expression of astaxanthin using the classical strain improvement methodology of repeated cycles of chemical mutagenesis and selection (see Figure 1) (Patent Application WO2021/019409, first publication date: 2021-02-04). These strains were characterized by two mutation points, CrtE and Erg20, which are genes involved in carotenoid synthesis, resulting in an astaxanthin yield increase from 0.02-0.04% up to 3.8% of dry weight after 7.5 days of incubation. Secondly, the carotenoid compounds were recovered from yeast through a solvent extraction process described in the patent application WO2021/137101 (first publication date: 2021-07-08), as shown in Figure 2.

Figure 1: Astaxanthin expression through multiple yeast generations (Start-up nation central).

Figure 2: Flow chart of method of manufacturing yeast astaxanthin by solvent extraction according to the patent application WO2021/137101.

During the extraction process, the heating treatment promotes the isomerization of all-trans astaxanthin into cis-isomers (from 6% to 51%), which allows for an increase in its antioxidant potency and bioavailability (Liu & Osawa, 2007). Due to this innovative process, the extracted astaxanthin has a higher stability, better absorption, a neutral flavor, and no aftertaste compared to algae astaxanthin. The patent families related to NextFerm’s core product, AstaFerm, and covering over-producing strains of Phaffia rhodozyma and an antioxidant extraction method with heat isomerization comprise foreign extensions published in Europe, the US, Canada, Australia, Korea, China, and India. These are strategic markets for dietary supplements with the largest shares and fastest growth rates. In 2020, NextFerm collaborated with California-based company Soft Gel Technologies to commercialize AstaFerm in the US through well-established and leading brands of the US food supplement market, such as Carlson, Grandhealth, and Purity Products. In July 2021, the company received regulatory marketing approval in Canada. Thanks to its neutral flavor, AstaFerm is usually combined with vitamin C in gummies, to improve the antioxidant effect of both and for a convenient and tasty drug delivery.

Entrance of biotech platforms into microbial astaxanthin market

NextFerm is not the only firm working on microbial astaxanthins. In 2021, the California-based company Biomedican developed a biosynthesis process using Phaffia rhodozyma for producing non-GMO and organic astaxanthin with a production cost that is 90% less expensive than chemical synthetic. Its product can be destined for both animal feed and human consumption. Another firm, Willow Biosciences, is currently optimizing the manufacturing process via precision fermentation using a high-yielding bioengineered yeast strain for pure, consistent, and sustainable astaxanthin. Interestingly, both biotech companies have commercialized the biosynthetic cannabinoid as their primary core product, and astaxanthin will be their diversifying product. However, for now, no commercial product or published patent application relating to astaxanthin from these two biotech companies has been recorded. NextFerm remains the key producer of natural non-algae astaxanthin for the dietary supplement market.

Microbial astaxanthin: a potential game-changer in the dietary supplement market

The health and nutritional benefits have boosted the high demand for natural astaxanthin. Although the market has largely been dominated by algae-based products, yeast astaxanthin still has a strong position due to its taste and quality advantages. The entrance of biotech newcomers with low-cost and sustainable production processes will significantly increase the share of natural microbial astaxanthin, eventually leading to market disruption.

Discover the IP capabilities of KnowMade in the field of medical sciences.

Press contact

contact@knowmade.fr

Le Drakkar, 2405 route des Dolines, 06560 Valbonne Sophia Antipolis, France

www.knowmade.com

About the author

An Nguyen, PhD. An Nguyen works at KnowMade as a Patent Analyst in the field of Biotechnology and Life Science. She holds a PhD in Biochemistry, chemistry and food technology from the University of Montpellier (France). She previously worked in food industry as R&D Engineer in vegan yogurt development. She is specialized in fermentation process, functional properties of dairy & plant proteins, encapsulation of bioactive compound.

About KnowMade

KnowMade is a technology intelligence and IP strategy consulting company specialized in analyzing patents and scientific publications. The company helps innovative companies, investors, and R&D organizations to understand competitive landscape, follow technological evolutions, reduce uncertainties, and identify opportunities and risks in terms of technology and intellectual property.

KnowMade’s analysts combine their strong technology expertise and in-depth knowledge of patents with powerful analytics tools and methodologies to turn patent information and scientific literature into actionable insights, providing high added value reports for decision makers working in R&D, innovation strategy, intellectual property, and marketing. Our experts provide prior art search, patent landscape analysis, freedom-to-operate analysis, IP due diligence, and monitoring services.

KnowMade has a solid expertise in Compound Semiconductors, Power Electronics, Batteries, RF Technologies & Wireless Communications, Solid-State Lighting & Display, Photonics, Memories, MEMS & Sensors, Semiconductor Packaging, Medical Devices, Medical Imaging, Microfluidics, Biotechnology, Pharmaceutics, and Agri-Food.