SOPHIA ANTIPOLIS, France – November 04, 2025 │ French biotechnology company Core Biogenesis has recently presented at Cosmetic 360, its oleosome-based growth factor platform promising anti-aging efficacy and supported by a sustainable and scientifically proven approach. Knowmade deciphers the science and the intellectual property behind the innovation.

About Core Biogenesis

Core Biogenesis is a biotechnology company founded in 2020, operating from its main headquarters in Strasbourg (France), where it has established both R&D and GMP-aligned biomanufacturing facilities dedicated to recombinant protein production in plant seeds. The company’s biotech platform, known as Core Bioprocess, focuses on plant-based molecular farming, using seed oleosomes for large-scale and animal-free production of growth factors and cytokines. Its Cosmetics & Personal Care platform leverages the same oleosome technology to formulate growth factor enriched actives for skincare applications. Together, these two platforms reflect Core Biogenesis’ dual positioning: industrial scale recombinant protein production for life science and sustainable bioactive ingredients for cosmetics, both anchored in eastern France.

The company’s patent portfolio is composed of two patent applications so far, for which Core Biogenesis shows a desire for a broad coverage as observed with these two WO applications.

A new step ahead in “longevity” skincare

The importance of growth factors in skin aging

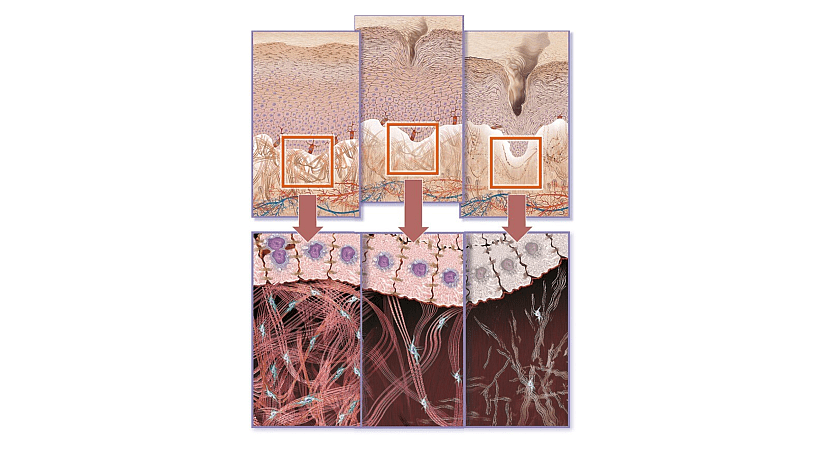

As the skin ages, changes occur in both the epidermis and the dermis. In the epidermis, corneocytes (terminally differentiated keratinocytes) accumulate and give the skin a rough and dull appearance. In the dermis, the collagen content decreases, leading to a disorganization and fragmentation of the collagen and elastin fibers network. This weakens the structure underlying the epidermis and results in the formation of wrinkles (Figure 1).

Growth factors are known to regulate cell growth and tissue repair and have been extensively studied in skin wound healing. They stimulate fibroblasts to boost the production of collagen and elastin, particularly Epidermal Growth Factor (EGF) and Fibroblast Growth Factor 2 (FGF2). They have shown similar potential as retinoids but without the irritative effects.

Growth factors decrease with aging. Several studies indicate that topically applied growth factors can promote skin rejuvenation, but their large molecular size (over 15 kDa) limits their ability to penetrate the tightly packed multiple skin layers. Indeed, it is generally impossible for molecules larger than 500 Da to penetrate the stratum corneum (the more external skin layer), preventing them from reaching the keratinocytes located deeper in the epidermis. To benefit from their potential in treating skin aging, their transport through the skin needs to be facilitated.

Figure 1: Changes observed in the skin with age (Aldag et al., 2016).

The left panels represent the structure of young skin, with an image of the epidermis and dermis (upper panel). The red square focus on the network of collagen and elastin fibers located in the dermis, that is magnified in the lower panel. The center panels represent the structure of mature skin, and the right panels the structure of aged skin.

The technology developed by Core Biogenesis

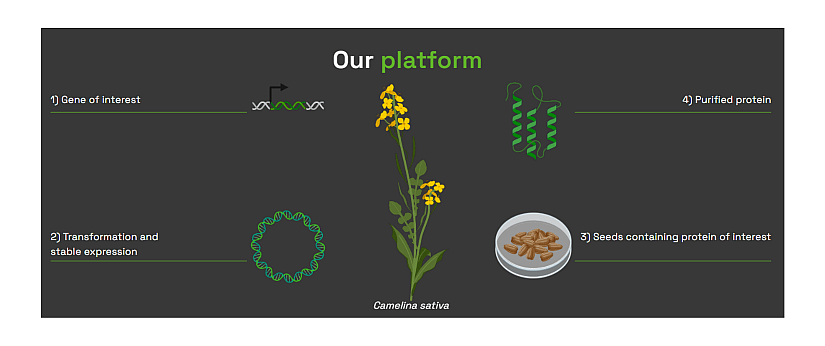

Using a plant bio-factory process, Core Biogenesis’ technology was designed for accumulating growth factors in the seeds of Camelina sativa, a plant from the Brassicaceae family (Figure 2).

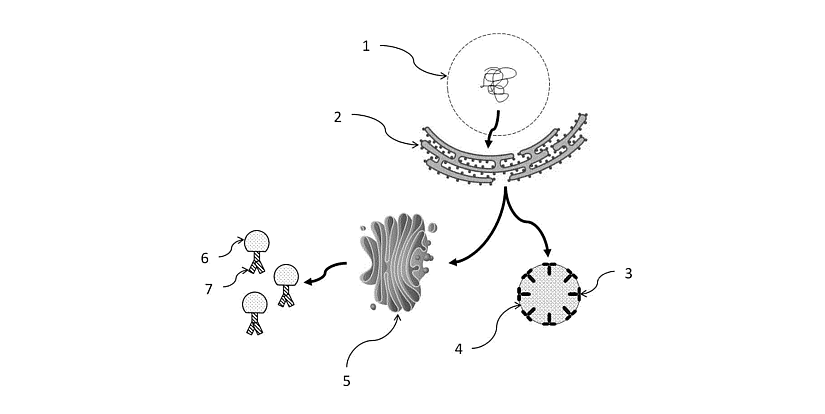

Figure 2: Overview of the technology developed by Core Biogenesis (from Core Bioprocess website).

Sequences of interest (human DNA from EGF or FGF2) are stably transformed into expression vectors, that are inserted into Camelina sativa genome. Seeds containing the proteins of interest (EGF or FGF2) are harvested before a final step of purification of the growth factors and their subsequent use in formulation by the cosmetic industry.

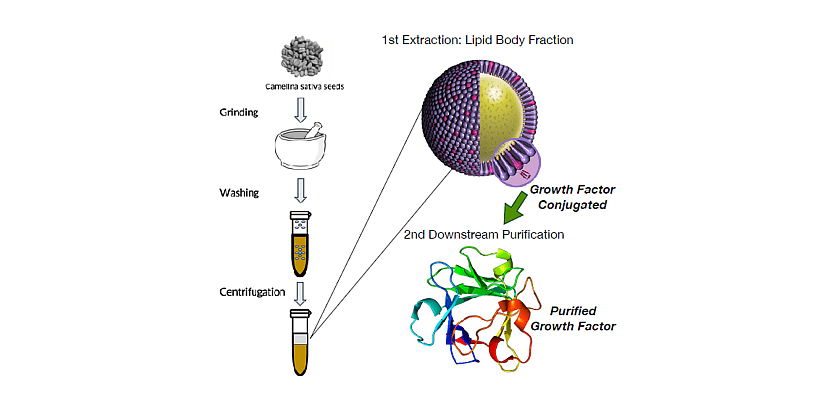

To improve their stability, growth factors are anchored to oleosomes’ surface. Oleosomes are oil droplets found in plant seeds. Composed of phospholipids, they encapsulate and protect a triacylglycerol (TAG) core (vegetable oil). Oleosomes are efficient carriers for large compounds, such as growth factors, that do not penetrate skin easily and degrade in less than seven hours at room temperature. Under these fusion structures, growth factors present a higher stability versus growth factor alone even in heat conditions. The bioproduction method developed by Core Biogenesis enables a targeted isolation of the recombinant growth factors within oleosomes located in the seeds, through a specific purification step ensuring a final protein product free of impurities (Figure 3).

Figure 3: Method used for the purification of recombinant growth factors fused to oleosomes (from Core Bioprocess website).

Seeds from Camelia sativa expressing recombinant growth factors are harvested, ground and washed, before being centrifuged. The lipid body fraction is separated to isolate oleosomes fused to growth factors, anchored at their surface. A step of purification is then used to separate the growth factors from the oleosin proteins.

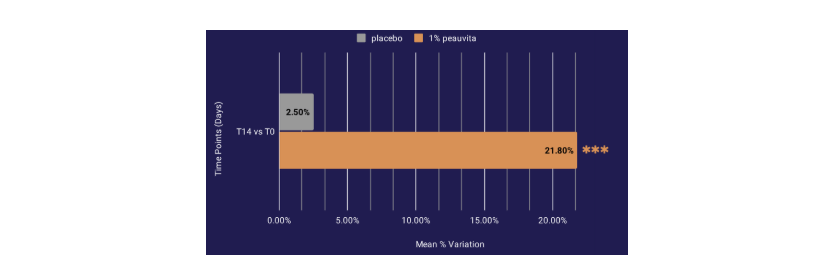

This technology offers an innovative alternative to address the primary signs of aging. With facilitated penetration through both epidermis and dermis, growth factors remain biologically active on the skin. Within fourteen days, EGF-oleosome fusion targets fine lines and wrinkles, and improves skin firmness (Figure 4), while FGF2-oleosome fusion reduces melanin and dark spots, and improves skin barrier in placebo-controlled studies.

Figure 4: Mean variation of skin firmness after topical application of Peauvita (EGF-oleosome fusion formulation) versus placebo (from Core Biogenesis website).

Topical application was performed twice a day for 14 days in groups of 20 subjects from various phototypes and ages. The passive behavior of the skin to suction force was used to measure skin firmness using a Cutometer.

The intellectual property behind Core Biogenesis’ innovative technology

The patent application WO2022/194652 describes a method to produce a genetically engineered plant allowing the synthesis of large quantities of recombinant proteins which are functional, can be easily extracted and purified and may be used for multiple applications. By inactivating genes involved in transcriptional gene silencing and post-translational gene silencing, plants can overpass the usual invasive nucleic acids regulation mechanism and express higher levels of recombinant proteins. The inventors have included nucleic acid constructs featuring strong promoters linked to coding sequences of recombinant proteins. The engineered plants, preferentially Camelina sativa, provide a cost-effective and efficient alternative to traditional fermentation systems, allowing for large-scale production of functional proteins. By inserting coding sequences for the oil body proteins (referred to as oleosomes) into the nucleic acid construct, the inventors can obtain a fusion protein that can be easily purified from oil bodies within the plant tissues.

According to the inventors, this invention, focusing on molecular farming, offers significant improvements over other methods by enabling higher yields of functional recombinant proteins through the inactivation of genes responsible for transcriptional and post-translational silencing, thus facilitating easier extraction and purification processes.

Filed in March 2022, this application is still pending in Canada, in the USA and in Europe, but the PCT application validity period expired in September 2024. Regarding the procedure, the International Search Authority’s written opinion has concluded that claim 1, directed to a genetically engineered plant intended for the production of recombinant proteins comprising a system aiming at inactivating transcriptional and post-translational gene silencing and a recombinant nucleic acid construct, is not novel. Indeed, the scientific article published by Jauvion et al. (2012), describing the role of polymerase enzymes in the mechanism of gene silencing appears prejudicial to the novelty. Similar conclusions were made for the scientific review published by Sharma & Sharma (2009) and the patent US2009/0197337 disclosing fusion proteins of oil body proteins with recombinant proteins. This method was also evaluated as non-inventive, based on the examination of the same documents. In addition, this application was concluded as being purely speculative as no experimental data were submitted. The claimed subject matter may not be patentable in some contracting states, as essentially biological methods for the production of plants and derived products are not considered as patentable under the European Patent Commission.

Later on, Core Biogenesis has completed this work by filing the patent application WO2023/099644, describing a method for the purification of recombinant proteins produced by genetically engineered plants, using oil body proteins, such as oleosins. This method involves mixing plant leaves with oil body proteins sourced from a different plant, where both recombinant proteins and oil body proteins are fused with an affinity ligand (Figure 5). This fusion facilitates the formation of complexes that can be efficiently recovered through flotation and separation. By utilizing transient expression techniques, the method allows for rapid production of functional proteins suitable for various applications.

Figure 5: Biogenesis of lipid bodies and fused proteins comprising an affinity ligand fused with a recombinant protein. From WO2023/099644.

The nucleus (1) of a cell of a first genetically engineered organism comprises the coding sequence for a recombinant protein in reading frame with an affinity ligand. When expressing such coding sequence, the complete biogenesis for the fused proteins follows the biosynthesis process from the nucleus, through the endoplasmic reticulum (2) and the Golgi apparatus (5). A fused protein comprises the affinity ligand (7) and the recombinant protein part (6). Lipid droplets (4) are also produced in cells and comprise lipid bodies which are useful for energy metabolism, membrane synthesis or the production of essential lipid-derived molecules. Oil body proteins (3) are also produced by the cells and are structural proteins which cover lipid droplets.

The process involves several steps: providing a first genetically engineered plant (Nicotinia benthamiana) expressing the recombinant protein of interest (IL-7 or IGF-1) via a CRISPR-Cas9 mutagenesis tool, mixing leaves of this plant with oil body proteins obtained from an oilseed plant (Camelina sativa), fusing the recombinant protein and/or the oil body proteins with an affinity ligand, forming complexes between oil body proteins and recombinant proteins, recovering these complexes by flotation of the mixture, and finally purifying the recombinant proteins and releasing them from the complexes. In this process, the affinity ligand (a single-chain variable fragment or single-domain antibody) plays a crucial role in binding the recombinant protein to the oil body surface, making recovery simpler and more specific.

According to the inventors, this method offers a rapid and efficient purification process for recombinant proteins, reducing costs and time compared to traditional methods. It allows for the production of mature proteins with proper post-translational modifications and avoids the complication of using tags for extraction.

Filed in December 2022, this application is still pending in the USA and in Israel, but the PCT application validity period expired in June 2025. Regarding the procedure, the ISA’s written opinion has concluded that claim 1, directed to a method for the purification of recombinant proteins produced by a first genetically engineered organism by mixing them with oil body proteins, fused with an affinity ligand, produced by another genetically engineered organism, is novel, as no document in the prior art discloses exactly such a method. Indeed, the patent application US2009282583 filed by Sembiosys Genetics, describes a method for the production of insulin in plants but without disclosing the step of mixing a first genetically engineered organism expressing the recombinant proteins with oil body proteins not obtained from the first engineered organism but prepared from a wild type seed. This method is also recognized as inventive, for the same reason, the ISA arguing that a person skilled in the art has no clue of how to arrive at the solution of this application based on the prior art consultation.

Conclusion

The innovation described in the patent applications WO2022/194652 and WO2023/099644 represent a significant advancement in plant-based recombinant protein production and purification systems. The application WO2022/194652 establishes genetically engineered plants, particularly Nicotinia benthamiana and Camelia sativa, with inactivated gene silencing pathways, thereby achieving high and stable expression of recombinant proteins, such as cytokines, enzymes and growth factors. The patent application WO2023/099644 complements this by introducing a novel purification strategy using oil body proteins (oleosins) that selectively bind recombinant proteins via affinity ligands, enabling their efficient recovery by flotation. Together, these technologies form a continuous platform, from enhanced expression to simplified purification, offering a cost-effective, scalable and environmentally sustainable solution for producing complex proteins, particularly growth factors, and antigens in plants with high yield and purity.

With their innovation, Core Biogenesis unveils an innovative oleosome growth factor platform, developed in France, and marking a breakthrough in skincare. Using molecular farming, the company produces plant-based bioidentical proteins through photosynthesis, reducing environmental impact. Clinical studies realized with their plant-produced growth factor-oleosome fusions show superior anti-aging effects compared to retinol, with greater wrinkle reduction, enhanced skin barrier function and no irritation. The oleosome system also ensures high stability, biocompatible penetration and controlled release of recombinant growth factors. This eco-conscious innovation redefines ethical and effective anti-aging treatments.

Press contact

contact@knowmade.fr

Le Drakkar, 2405 route des Dolines, 06560 Valbonne Sophia Antipolis, France

www.knowmade.com

About the author

Céline Gaudel, PhD., works at KnowMade in the field of Biotechnology and Life Science. She holds a PhD in Molecular and Cellular Biology from the University of Nice Sophia-Antipolis (France). She previously worked in academic research in France and Ireland and has a background in skin science and cosmetic ingredients.

About KnowMade

KnowMade is a technology intelligence and IP strategy firm specializing in the analysis of patents and scientific publications. We assist innovative companies, investors, and research organizations in understanding the competitive landscape, anticipating technological trends, identifying opportunities and risks, improving their R&D, and shaping effective IP strategies.

KnowMade’s analysts combine their strong technology expertise and in-depth knowledge of patents with powerful analytics tools and methodologies to transform patent and scientific data into actionable insights to support decision-making in R&D, innovation, investment, and intellectual property.

KnowMade has solid expertise in Semiconductors and Packaging, Power Electronics, Batteries and Energy Management, RF and Wireless Communications, Photonics, MEMS, Sensing and Imaging, Medical Devices, Biotechnology, Pharmaceuticals, and Agri-Food.