SOPHIA ANTIPOLIS, France – November 19, 2025 │ The lithium-ion battery (LIB) recycling landscape is currently in its developing stage, shifting from research phase to industrial demonstration and full supply chain integration. What seemed once a complementary approach to material supply from international partners has rapidly acquired the status of strategic interest for a whole industrial ecosystem, with governments and OEMs prioritizing local supply, traceability, and circularity. This transition touches every tier of the value chain: upstream, midstream and, increasingly, end‑of‑life management through recycling and re‑manufacture.

The policy environment has accelerated the shift. Circular‑economy mandates and recycled‑content requirements are reshaping procurement criteria, pushing companies to deliver domestically sourced materials with robust data on provenance and emissions. At the same time, the global battery industry has seen a seemingly sudden but long brewed policy shifts, from US tariffs to Chinese technology and materials export blockades and all the cascade effect on Europe.

Whether sudden or not, LIB recycling moved from being part of the process to a strategically valuable stage in securing stable, efficient and equally profitable supply chain. The result is a race to secure materials feed while maintaining competitive costs and quality.

While the Chinese LIB industrial system is massively researching every possible aspect in the LIB manufacturing ecosystem, with many intellectual property (IP) players in the recycling field with global relevance [1], companies from other parts of the world did not stand still and fuelled the competition. “As highlighted in our recent report LIB Cathode Active Materials Recycling – Patent Landscape Analysis 2025, the IP competition across the globe is fierce, fast-paced and multi-faceted”, says KnowMade’s Technology Analyst Dr. Filippo Farina.

Over the next few years, as more factories ramp come into completion, Europe’s LIB recycling landscape will be defined by who can execute this integration fastest, turning geopolitical pressure into durable materials sovereignty without sacrificing economics or quality.

Efforts from European companies like Umicore, Cylib, Eramet & Suez, HydroVolt, Veolia, SNAM and Mecaware highlight European domestic advancements as a strategic tool, which comes nonetheless with the participation of other companies from overseas.

Ascend Elements: a rapid growth in the dynamic US landscape

The North American landscape comprises a whole ecosystem of LIB players, ranging from raw materials suppliers to battery manufacturers, OEMs, and recyclers. It is precisely in this latter segment that a U.S. company has built and secured its niche, while seeking to establish its influence overseas. Ascend Elements is a recycling company focused on Li-ion batteries, founded in 2015 as a spin-out of the Worcester Polytechnic Institute to develop commercially their research activities ongoing since 2011 to develop NMC recycling methods, and has been growing steadily ever since. After securing funding through multiple grants and investment rounds, its industrial activities were first implemented in their headquarters state of Massachusetts, before expanding to Michigan and Georgia from 2020 onward [2]. Recycling of Cathode Active Materials (CAM) is Ascend Elements’ core business, represented by the introduction of its Hydro-to-Cathode® technology for CAM precursors (pCAM) synthesis process. The company delivered its first commercial shipment of refined pCAM in the form of Lithium Carbonate (Li2CO3) in early 2025 [3], and its road to domestic success seems to be on the right path.

While establishing credibility in its home country, in recent years Ascend Elements’ view expanded overseas on European shores, finding a suitable environment in Poland. In this new context, Strategic Elemental Metals was more than keen to partner with a ramping company to establish a joint venture on Polish ground [4]. This agreement will strengthen Ascend Elements’ position beyond the US and mark its entry into foreign markets.

A focused IP portfolio

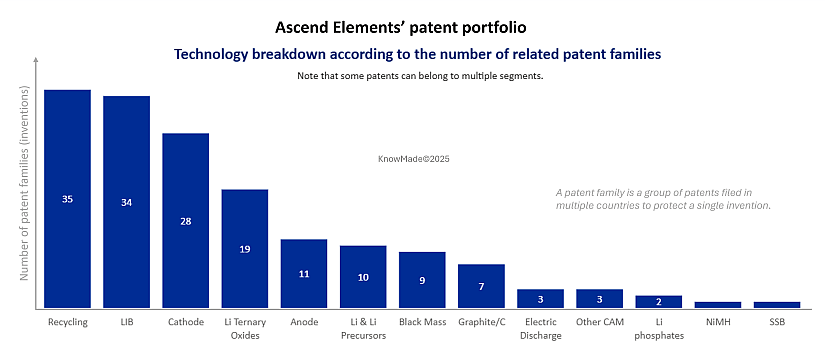

As an IP player in the field of LIB recycling, Ascend Elements devoted its focus to CAM treatment since its inception. Over time, additional activities in Graphite and Lithium precursors recycling and refining were explored. At present, Ascend Elements’ published patent portfolio comprises 35 patent families (inventions) grouping 119 individual patents, with its technological segmentation summarized as follows:

Figure 1: Technological segmentation of current Ascend Elements’ patent portfolio (Note: a single patent family can be assigned to multiple segments).

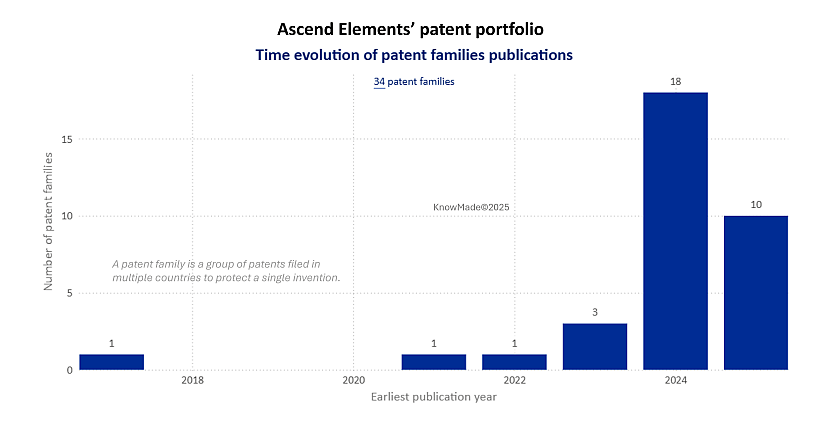

As is evident, most of the intellectual property focuses on protecting CAM-related methods and processes, with a clear predominance of lithium ternary oxides. Most of patents have been published over the past 3 years, with a noticeable peak in 2024.

Figure 2: Publications timeline of Ascend Elements’ patent families

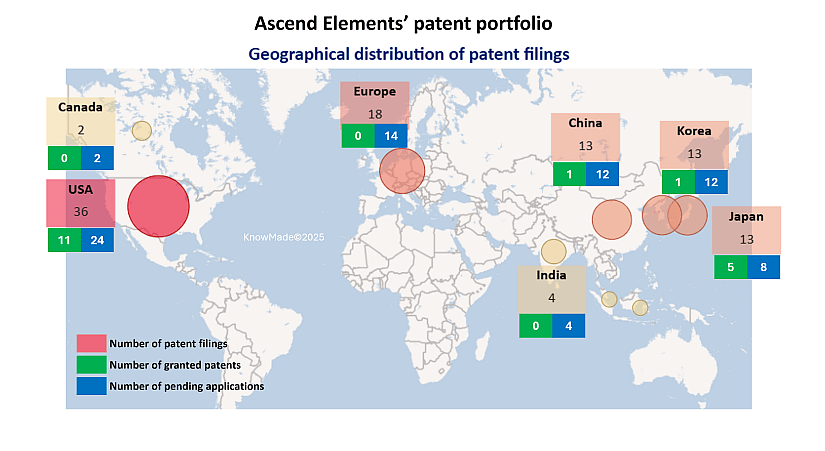

Ascend Elements’ geographic strategy has been initially focused mainly over the USA, with successive patent publications in all major world locations. Up to today, the USA remain the main jurisdiction where patents are filed, followed by Europe, China and South Korea. The years 2023-24 saw the most IP activity, with over half of the total Ascend Elements’ patent publications, while 2025 saw patent filings only in the USA and PCT applications.

Figure 3: Geographical distribution of Ascend Elements’ granted patents and pending patent applications

The commercial expansion of Ascend Elements led to the creation of the joint venture AE Elements in partnership with Elemental Strategic Metals, which, is set to further develop the industrial capabilities of both companies in Europe, starting from Poland and already planning to build another facility in Germany [5]. This partnership enables the new entity to exploit the combined know-how of its parent companies; with Elemental Strategic Metals bringing extensive expertise in metals, the joint venture significantly broadens its technical capabilities. Its IP portfolio is composed by 4 patent families, currently regrouping patents filed in Poland only; their focus is mainly on the recovery of various active metals from LIB black mass (Li, Co, Mn, Ni) but also other elements present in the mix (Graphite, Cu, Fe, Al, F).

With its expertise in metal treatment and refining, Elemental Strategic Metals provides further expertise for the LIB recycling value chain in Europe.

Examples of Ascend Elements and partner’s IP portfolios

The IP portfolio under the name of Ascend Elements comprises several patents that have ignite interest from other patent applicants, as evidenced by the total number of citations. One patent family has been cited an impressive 232 times, while a handful of others have received up to 30 citations each. In this section, we present some examples of patents from Ascend Elements and Elemental Strategic Metals to provide the reader with a glimpse of the technological capabilities of these two players.

A key patent from Ascend Elements’ portfolio

Method and apparatus for recycling lithium-ion batteries – US10522884

The most cited patent family of the portfolio was initially filed by Worcester Polytechnic Institute and is today co-assigned to Ascend Elements. As an example of its content, here we will show the patent US10522884, first published in 2017 and then granted in 2020. Its patent family includes patents granted in USA and South Korea, and other pending patent applications in China, Japan and European jurisdictions, covering many of the most important market areas.

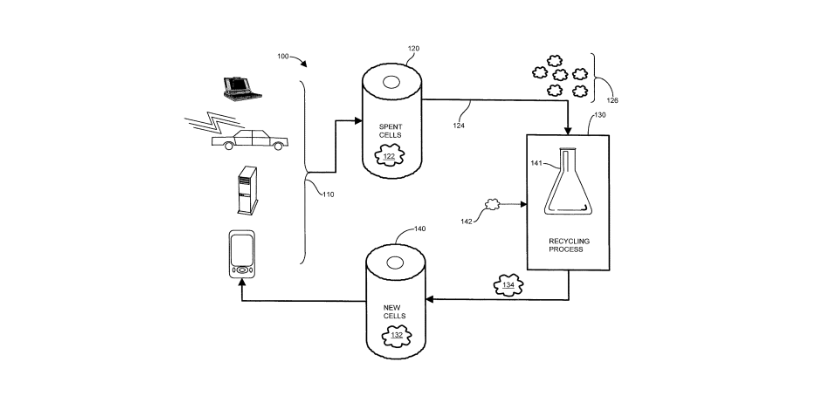

The patented invention discloses a method and an apparatus for LIB recycling, allowing to recover elements such as Co, Ni, Mn and Al at the same time (see figure).

Figure 4: Schematics of the invention in patent US10522884

The patent claims a solution method to isolate the key metals component of a Cathode Active Materials issued from black mass from recovered Li-ion batteries; there is no preferred cathode chemistry, although the method is particularly apt to recover metals commonly used in CAM such as NMC, NCA and LCO.

In this invention, after a preliminary leaching with Sulfuric Acid and Hydrogen Peroxide at mild temperatures to solubilise the metals, the addition of Sodium Hydroxide allows to precipitate metals hydroxides of Fe, Al, and Cu. The ratio of the metals remaining into the leached solution is then analysed and, if needed, supplemented with the lacking metals in their Sulphate form. After this stage, the pH is gradually increased using Sodium Hydroxide to recover the hydroxide form of NMC or NCA if Al is present; Lithium Carbonate is also isolated. After this step, the remaining hydroxide is calcined to obtain a pristine CAM ready to be reused in the cathode manufacturing process.

A less common target material for recycling companies in LIB

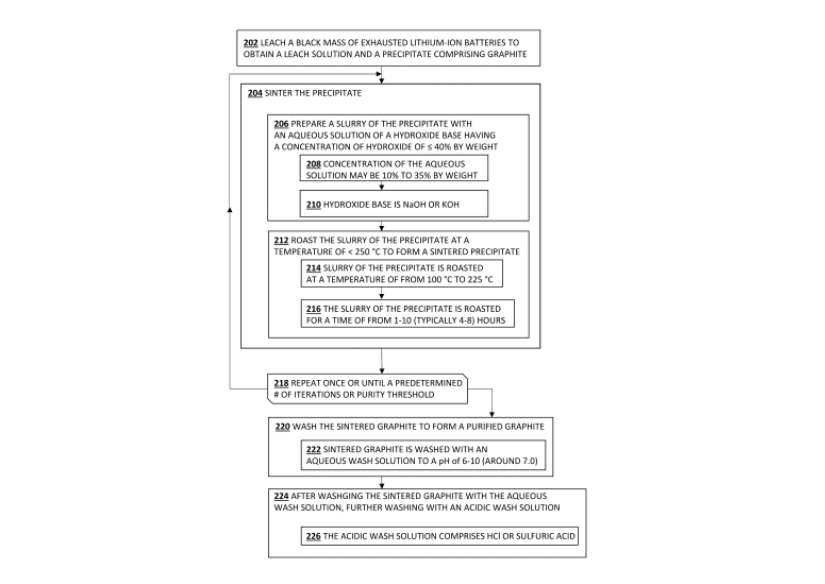

Recycled Graphite for Li-Ion Batteries – JP7649364

The invention is currently protected in Japan (granted patent JP7649364), but related patent family also regroups other patent applications currently awaiting approval in Europe, USA, South Korea, and China. The invention reports a method to recover Graphite from the black mass resulting from the crushing of Li- or Na-based batteries. After impurities removal, the material is treated in alkaline environment; after other washing steps, both neutral and acid, all active metals are isolated, and the Graphite can be extracted. A sintering step allows to refine the Graphite in high purity, ready to be reused in novel electrode manufacturing.

Figure 5: Schematics of the invention claimed in patent JP7649364

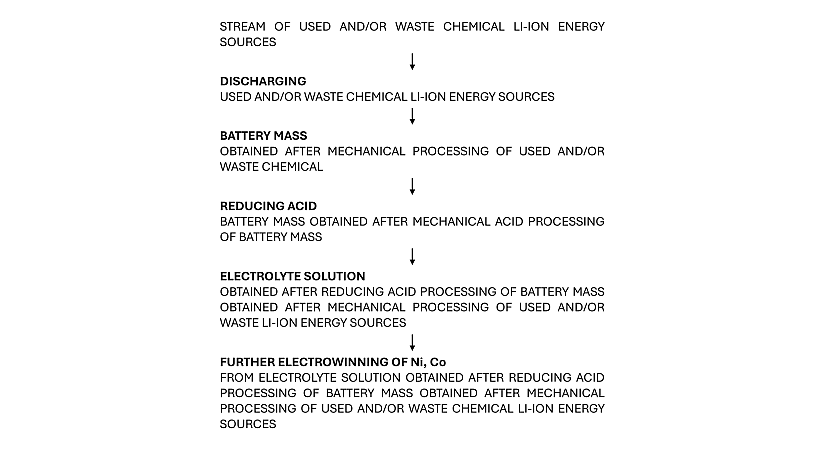

A patent from Elemental Strategic Metals’ portfolio

Method of carrying out the recovery process of cobalt, nickel and manganese(IV) oxide from electrolytes obtained as a result of leaching black mass recovered from used lithium-ion batteries – PL246860

The patent PL2146860 from Elemental Strategic Metals describes an electrochemical method to recover metals from a leaching solution from spent LIB black mass. The electroseparation process originates in the first step Co and Cu on the cathode and MnO2 on the anode; after a second step Ni is deposited on the cathode.

Figure 6: Process described in patent PL2146860 (readapted image)

This method allows the precise recovery of key elements from spent LIB active materials. The expertise in metals electroseparation from Elemental Strategic Metals well complements the LIB recycling expertise from Ascend Elements, offering a wider range of choice and operational possibilities to their joint venture AE Elemental.

Conclusion

As the global lithium-ion battery industry races toward circularity, Ascend Elements stands out as a dynamic and strategically aligned player. Rooted in US innovation and now expanding into Europe, the company has successfully positioned itself as a credible player in LIB recycling.

From its US headquarters Ascend Elements’ strategic pivot into Europe through its joint venture with Elemental Strategic Metals underscores its global ambition. The establishment of AE Elemental in Poland, and planned capacity in Germany, show a clear commitment to localizing circular battery materials in a region racing to build strategic autonomy.

Intellectual property is another core asset. With over 100 patents spread across cathode materials, anodes, and lithium recovery technologies, Ascend Elements not only manufactures but also protects knowledge critical to next-generation supply chains. The high citation rate of some patent families highlights the relevance and technological impact of their innovation.

This IP approach gives Ascend Elements a competitive edge in a sector where traceability, performance, and regulatory alignment are no longer optional. As battery recycling transitions from waste management to value generation, companies are shaping what circularity means in the real world. The recent joint venture AE Elementals created with Elemental Strategic Metals marks a further step in Ascend Elements’ strategy in Europe, highlighting the full commitment to developing a fully functioning recycling ecosystem for LIBs.

In the coming years, much will depend on the execution: facility ramp-ups, feedstock sourcing, offtake agreements, and the evolution of international partnerships. But for now, Ascend Elements offers credibility and a good example of how strategic focus, IP leadership, and industrial deployment can build solid positions in the fast-evolving battery economy.

Sources:

https://ascendelements.com/about-us/

Press contact

contact@knowmade.fr

Le Drakkar, 2405 route des Dolines, 06560 Valbonne Sophia Antipolis, France

www.knowmade.com

About the author

Filippo Farina, PhD. works at KnowMade as Patent & Technology Analyst in the field of Energy Storage and Conversion. He holds a PhD in Materials Chemistry from the University of Montpellier (France). After spending few years in industry (Morgan Avanced Materials, EcoLab), he has been working since 2015 on materials for batteries and fuel cells at University of Montpellier, CNRS and CEA-LITEN (France). Contact: filippo.farina@knowmade.fr .

About KnowMade

KnowMade is a technology intelligence and IP strategy firm specializing in the analysis of patents and scientific publications. We assist innovative companies, investors, and research organizations in understanding the competitive landscape, anticipating technological trends, identifying opportunities and risks, improving their R&D, and shaping effective IP strategies.

KnowMade’s analysts combine their strong technology expertise and in-depth knowledge of patents with powerful analytics tools and methodologies to transform patent and scientific data into actionable insights to support decision-making in R&D, innovation, investment, and intellectual property.

KnowMade has solid expertise in Semiconductors and Packaging, Power Electronics, Batteries and Energy Management, RF and Wireless Communications, Photonics, MEMS, Sensing and Imaging, Medical Devices, Biotechnology, Pharmaceuticals, and Agri-Food.