SOPHIA ANTIPOLIS, France – 21 July, 2025 │The Northvolt case is a textbook example of growth and bankruptcy in the field of lithium-ion battery production, albeit with a portfolio of interesting patents on the sidelines. We analyzed the situation from a patent perspective, and here’s our take.

From Gigafactory Dreams to Bankruptcy: Northvolt’s Rise and Fall

In 2016, Northvolt was founded by ex-Tesla executives Peter Carlsson and Paolo Cerruti with the ambitious aim of establishing Europe’s first domestically grown lithium-ion cell gigafactory, thereby reducing reliance on Asian suppliers. The company quickly garnered significant financial backing, raising over $15 billion from investors, enabling it to commission the Northvolt Ett facility in Skellefteå in December 2021. Strategic joint ventures were formed, notably with Volkswagen in 2019 to create Northvolt Zwei in Salzgitter, Volvo Cars in 2021 for NOVO Energy AB in Torslanda, and Norsk Hydro in 2020 to establish Hydrovolt in Fredrikstad. In addition, Northvolt acquired the US start-up Cuberg in March 2021.

Despite its rapid growth and strategic partnerships, Northvolt encountered insurmountable challenges, including escalating capital costs, logistical setbacks, and critical disruptions in the global supply chain. These difficulties compelled the company to file for Chapter 11 protection in the United States on November 21, 2024, restructuring approximately $5.8 billion in debt. Ultimately, Northvolt declared bankruptcy in Sweden on March 12, 2025, triggering segmented sales of its tangible and joint-venture-linked assets to different buyers, rather than a single purchaser. The joint ventures saw their co-owners acquiring Northvolt’s shares: Norsk Hydro took full control of Hydrovolt in January 2025; Volvo Cars secured NOVO Energy in October 2024; and Volkswagen fully integrated the JV Northvolt Salzgitter in 2021, now managed by Power Co. Lyten acquired Northvolt’s Cuberg lithium-metal anode production lines in November 2024 and further expanded its European presence by purchasing the ESS facility in Gdańsk, Poland, in July 2025. Additionally, Scania acquired Northvolt Systems’ industrial division in April 2025, renaming it Scania Industrial Battery Systems.

Significantly, Northvolt’s substantial patent portfolio, comprising 213 patent families, remains under the custodianship of court-appointed trustee Mikael Kubu. He was appointed by the Stockholm District Court to oversee the sale and management of these intellectual property (IP) assets following the bankruptcy. The final liquidation, including the distribution of IP and tangible assets, is expected to conclude by late 2025. Throughout the liquidation period, trustee Kubu administers Northvolt’s IP portfolio, overseeing patent maintenance, prosecution, and licensing activities. This comprehensive divestment of tangible assets opens an opportunity to deeply explore Northvolt’s remaining IP holdings, specifically understanding the scope of its patent portfolio and examining how these technological innovations might shape the future trajectory of the battery industry.

Northvolt: A Recent and Promising patent Portfolio

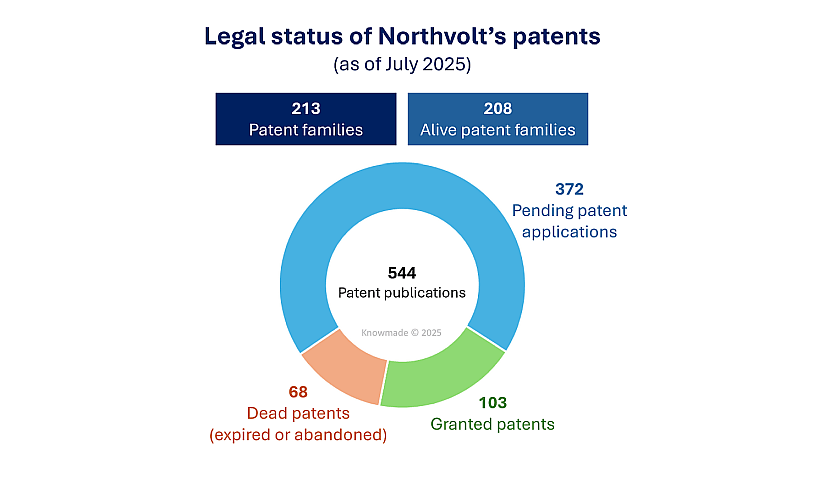

Northvolt’s patent portfolio comprises 213 patent families (i.e., inventions protected by groups of patents or patent applications across multiple countries), with 208 alive patent families, resulting in 544 patent publications (103 granted and 372 pending applications), highlighting Northvolt’s substantial innovation efforts. This includes 23 patent families filed under the brand Cuberg (10 granted, 17 pending applications).

Northvolt’s innovation drive was abruptly cut short by its liquidation

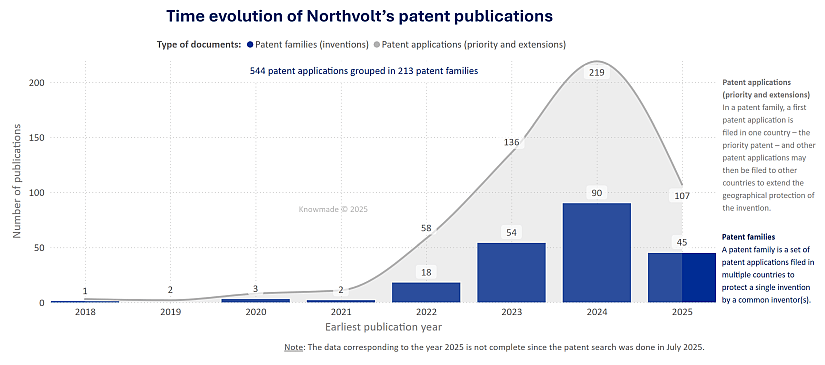

Figure 1: Time evolution of Northvolt’s patent publications (as of July 2025).

The patent publication timeline highlights Northvolt’s rapid increase in patent activity starting from 2018, with a marked acceleration from 2022 onwards. The highest volume of patent publications occurred in 2024, reflecting the company’s intense innovation efforts in its later operational years. With Northvolt’s financial difficulties, this patent filing momentum has slowed down, and with 45 patent families published as of July 2025, the number of publications is expected to remain the same as in 2024. It’s important to remember that patent publications typically occur 18 months after the filing date; thus, many filings made shortly before or during Northvolt’s financial distress in 2024 and early 2025 might still be awaiting publication.

From Europe to PCT: Northvolt’s Global Patent Surge

Figure 2: Legal status of Northvolt’s patents (as of July 2025).

Northvolt’s patent portfolio predominantly consists of recent patent applications, primarily filed from 2023 onward, leading to an higher number of pending patent applications (372) than granted patents (103). This reflects the company’s intensive innovation efforts during its later operational years. The high proportion of pending patent applications suggests a potential significant strengthening of the enforceable patent portfolio, should all these patent applications be granted.

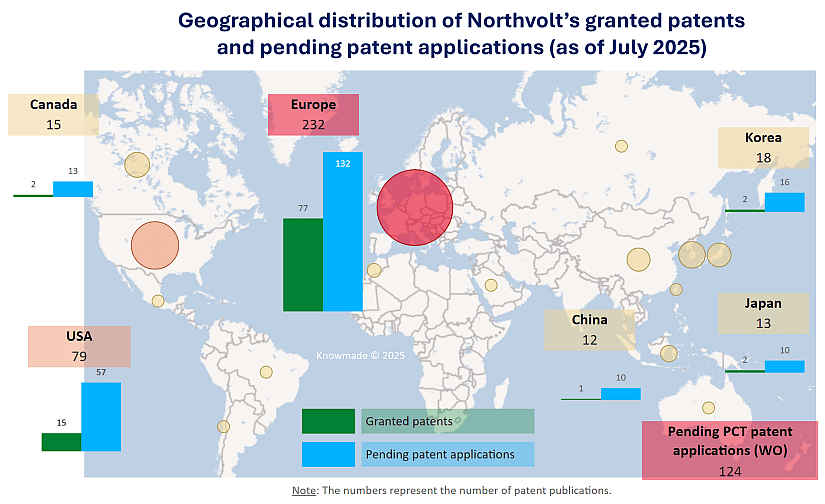

Figure 3: Filing countries and current legal status of Northvolt’s patent applications.

Geographically, Northvolt’s patents have a pronounced presence in Europe, with 232 patent filings (currently 77 granted patents and 132 pending applications), reflecting their strategic focus on this market. The United States follows with 79 filings (15 granted, 57 pending). Additionally, notable filings are observed in Canada (15), Korea (18), Japan (13), and China (12), alongside a substantial number (124) of international pending applications filed under the Patent Cooperation Treaty (PCT), demonstrating Northvolt’s aim for extensive international protection of its technology innovations.

External Citation Impact: Measuring Northvolt’s Industry Influence

“Patent citation analysis is instrumental in assessing the technological relevance, influence, and potential value of a company’s innovations. Citations received from other patent applicants reflect the recognition and reliance of the industry on that invention, indicating its foundational or pioneering nature. This analytical method helps highlight key innovations and their impact within technological ecosystems. Furthermore, citations analysis can provide valuable insights into potential buyers, as companies citing a patent may have an interest in acquiring it to secure their technology’s foundation or to reinforce their IP position.”, explains Fleur Thissandier, PhD, Senior Technology and Patent Analyst at KnowMade.

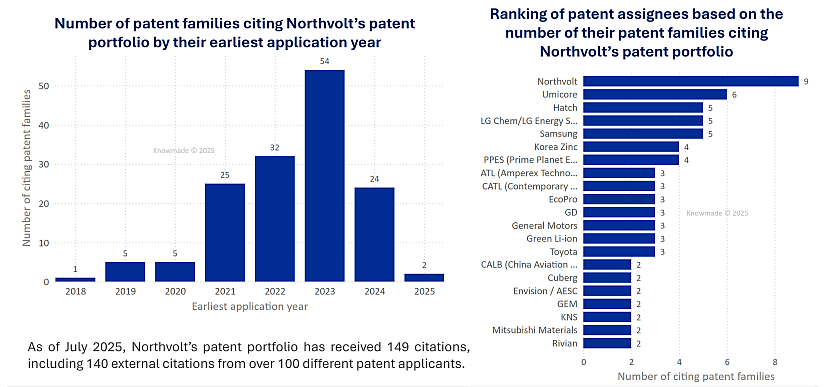

Despite its relatively young patent portfolio, Northvolt’s patents have received a notable number of citations, highlighting significant technological impact of its inventions in the field. With over 140 external citations from more than 100 different patent assignees, Northvolt’s technologies have quickly captured significant attention. The citation activity notably increased around 2020, peaking in subsequent years, underscoring Northvolt’s growing influence. Prominent citing patent assignees citing Northvolt’s patents include major battery and automotive industry leaders such as Umicore, Hatch, LG Chem/LG Energy Solution, Samsung, PPES, CATL, EcoPro, Korea Zinc, CALB, Envision/AESC, General Motors, Mitsubishi Materials, Rivian, BASF, SK On, SVOLT, Toda Kogyo, Varta and Verkor further demonstrating the rapid impact and relevance of Northvolt’s innovations.

Figure 4: Analysis of patent families citing Northvolt’s patent portfolio (“citing patent families”): a) Time evolution of forward citations received by Northvolt’s patents, b) Ranking of patent assignees based on the number of their patent families citing Northvolt’s patents.

Seven patent families held by Northvolt have each received more than five forward citations. All patents of these families are either in force or pending in at least three key market regions: the US, Europe, and Asia (Japan, China, and/or South Korea).

- An important patent family (WO2022/009004, 36 citations), co‑owned with Hatch, has patents granted in Europe, Turkey and the US and pending applications in Australia, Brazil, Canada, Chile, Indonesia, China, Japan and Korea. It discloses a process and method for producing crystallized metal sulfates. In Europe, Umicore has filed an opposition against the patent EP3945068 of this family.

- Another key patent family (WO2020/212363, 16 citations), granted in the US, Europe, Canada and Japan and pending in Korea, describes a phosphoric-acid–based process for precipitating and removing aluminum and iron impurities from leachates to enable further recovery of NMC metals and lithium. In Europe, Framet has filed opposition against the EP3956487.

- The patent family WO2022/053448 (7 citations), co‑owned with Metal Trade Overseas, has granted patents in Europe and Morocco while patent filings are pending in Canada, China, Japan, Indonesia, South Korea and the US. It claims a process for preparing battery-grade metal sulfate solutions. Umicore and Nikkelverk/Glencore have filed opposition against the EP3967661.

- One more patent family (WO2023/031108, 8 citations) with patents granted in the US and pending applications in Europe and South Korea, covers a casing design that improves electrode-assembly support and connection.

- The patent family WO2022/167662 (7 citations) has all its applications pending in Canada, China, Europe, Indonesia, Japan, South Korea, Morocco, Taiwan and the US, and it relates to preparing cathode-active-material precursors from Ni–Mn–Co leachates.

- The invention disclosed by the patent family WO2022/223531 (6 citations) details a cylindrical secondary cell with a specific design. The patents are granted in Sweden and the US, and applications remain pending in China, Europe, Japan and South Korea.

- Another patent family (WO2022/144127, 5 citations) with granted patents in Europe and the US, and pending applications in Canada, China, Japan and South Korea, claims both a terminal for a secondary cell and its matching rivet.

Seven additional patent families of Northvolt have also live patents (granted or pending) in the US, Europe, and Asia (Japan, China, and/or South Korea), but have received fewer forward citations. One of them is already granted in the US (US11757160, US11664561). It covers a battery cell with a specific electrode lead plate with integrated fuse functionality. Another family has already a patent granted in Europe (EP4360161). It discloses an electrode assembly with improved connection regions for lithium-ion batteries. The other patent families have applications still pending in the US, Europe, and Asia. One of them relates to a fluoride removal process (WO2023/088955); another describes a process for recovering battery active-material concentrate (WO2023/111248); and a third covers a process for efficient metal recovery from lithium-ion battery feedstocks (WO2023/175161). The last two concern a cylindrical secondary cell with an integrated venting terminal (WO2022/167586) and an electrochemical cell with a sealant (WO2022/238514), respectively.

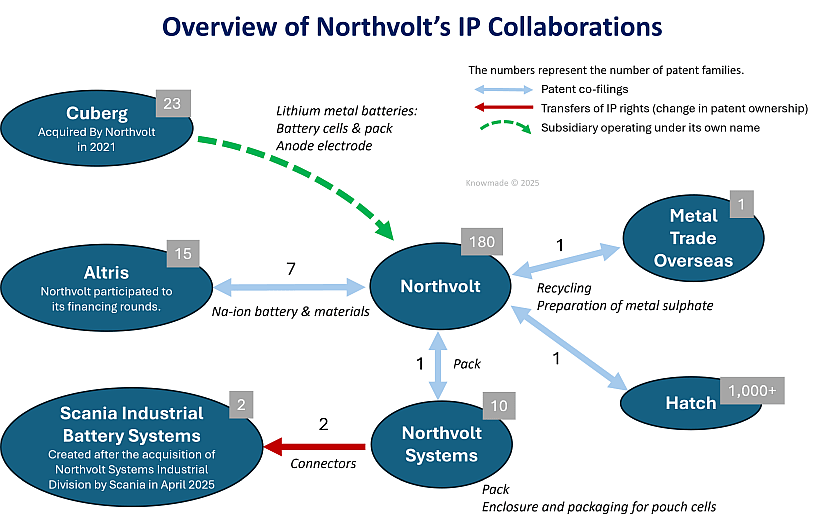

Northvolt’s Strategic IP Collaborations and Transfers

Northvolt adopted a collaborative approach to intellectual property, engaging selectively in patent co-filings, IP transfers, and subsidiary management. The acquisition of Cuberg in 2021 contributed to technological developments in lithium-ion battery cells and anode materials. Similarly, Northvolt’s partnership with Altris facilitated joint innovations in sodium-ion battery technologies and materials. IP transfers also occurred with Scania Industrial Battery Systems following Scania’s acquisition of Northvolt Systems’ industrial division. Additional specialized interactions with companies such as Metal Trade Overseas and Hatch supported specific technological advancements, although their overall impact on Northvolt’s broader IP strategy appears more limited and focused.

Figure 5: Scheme of Northvolt’s IP collaborations and transfers.

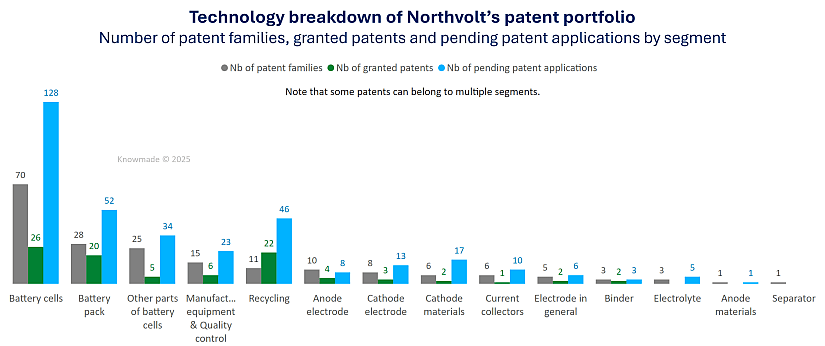

Technological Deep Dive into Northvolt’s Innovations

Beyond the statistical overview of Northvolt’s IP, patent analysis can provide strategic insights into the specific technologies covered by Northvolt’s patent portfolio. Northvolt’s patents focus on lithium-ion battery technologies and comprehensively cover the entire battery supply chain, from active materials and essential components to their integration into battery cells and packs, as well as recycling methods.

Figure 6: Technology breakdown of Northvolt’s patent portfolio.

Northvolt’s IP portfolio addresses key contemporary technological challenges, including Si/SiOx anodes, NMC cathodes, electrolyte additives, inorganic/polymer separators, non-PFAS binders, dry electrode processing, tabless electrode configurations, advanced safety and thermal management strategies at both the cell and pack levels, recycling technologies, and in-line quality monitoring solutions. This broad technological scope demonstrates Northvolt’s strategic commitment to innovation across critical areas of battery development and sustainability.

Materials & Electrolyte Innovations: Silicon Anodes, NMC(A) Cathodes and Compatibles Electrolytes and Separators

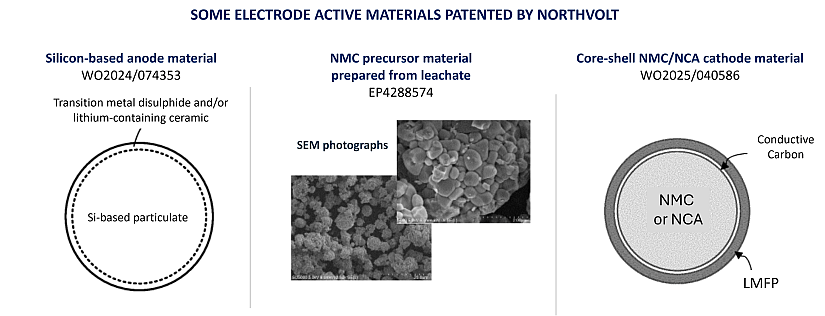

Anode Materials: Northvolt’s innovations in anode materials focus notably on enhancing silicon-based anodes. One significant advancement includes silicon particles coated with a ceramic layer incorporating transition metal disulfides or lithium-containing ceramics, as described in patent WO2024/074353. This approach aims to enhance the lithiation kinetics of silicon-based anodes, reducing capacity fading during cycling, and allowing for the use of cheaper, more abundant materials while maintaining high energy density.

Cathode Materials: Northvolt’s cathode material patented technologies primarily revolve around NMC/NCA chemistries. They include advanced materials coated with various functional coatings such as LMFP, carbon black, graphene, and Li₃PO₄. Additionally, Northvolt has developed a washing and purification process for cathode active materials to significantly reduce impurity levels. Other innovations include NMC doped with diverse doping elements (Ta, Ru, Os, Al, B, Ti, etc.) and/or partial anion substitution (by S, N, F, etc.). One notable patent claiming these materials (EP3636597), is notably cited by Umicore and AirLiquide/Valtaix. Another highly notable innovation (EP4288574), cited by Green Li-ion, Ascend Elements, Rivian and SK Group, concerns cathode active material precursor preparation from a leachate comprising Ni, Mn and Co.

Figure 7: Schemes of some electrode active materials patented by Northvolt, extracted from patents WO2024/074353, EP4288574, and WO2025/040586.

Electrolytes: The electrolyte formulations developed by Northvolt are specifically designed to be compatible with advanced anode-cathode-separator combinations, particularly Si/SiOx-NMC systems paired with inorganic-coated separators. Innovations include multi-salt, non-aqueous electrolytes with diverse solvent additives such as fluorinated organic carbonates, alkyl-propionates, acetonitrile, pyridine, and various C₁–C₈ hydrofluoroethers (HFEs), enhancing battery stability and performance.

Separators: Northvolt’s advancements in separators are exemplified by the development of porous separators incorporating functionalized inorganic particles, as detailed in patent WO2023/138846. This design reduces the risk of dendrite formation and enhances ionic conductivity.

Electrode Design: Replacing PFAs Binders, Advanced Electrode Assemblies & Compositions

Current Collectors: Northvolt has patented several current collectors with different improved properties: enhanced electrical contact reliability, controlled electrical resistance, improved mechanical protection and structural integrity, optimized electrolyte flow and overall cell performance, simplified and cost-efficient assembly processes.

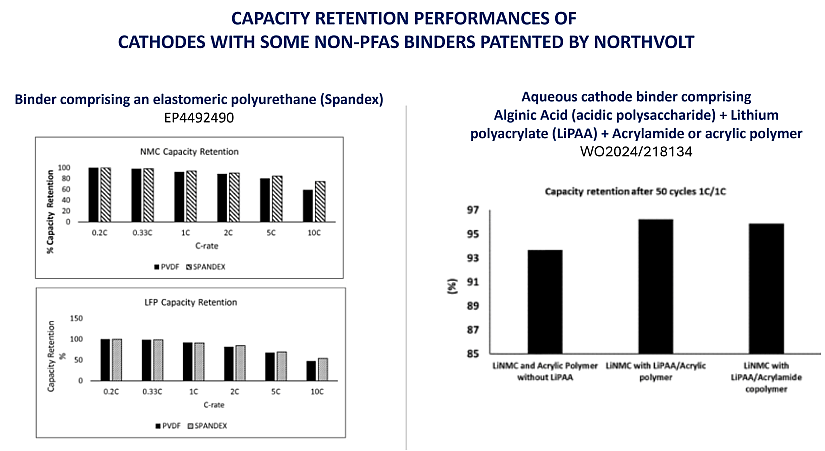

Binders: Northvolt’s innovative approaches to binders emphasize replacing conventional fluorinated compounds (PFAs). Key developments include the use of elastomeric polyurethane binders in lithium-ion cathodes (SE2351053), a combination of chitosan-grafted polyaniline with styrene-butadiene rubber (SBR) or carboxymethylcellulose (CMC) for Si/graphite anodes (EP4548412), and blends of poly(acrylic acid) (PAA) with polyvinyl butyral (PVB) for cathode compositions (SE2251525), eliminating the need for hazardous N-methyl-2-pyrrolidone (NMP) solvents.

Anode Electrodes: Northvolt patented technologies feature significant innovations on silicon-based anodes such as the incorporation of polymer-encapsulated lithium metal active materials and the use of chitosan/PAA binders. Additionally, Northvolt developed structured anode architectures with surface cavities or vertically-oriented carbon particles. Notably, the company developed polymer-rich edge coatings (PVDF, PVB, HNBR, Polyisobutene) applied to electrode foils, improving coating control and cell sealing.

Cathode Electrodes: Northvolt’s cathode electrode innovations include metal oxide coatings on cathode active materials applied via Atomic Layer Deposition (ALD), solvent-free cathode compositions using nitrile rubber suitable for high-temperature extrusion, polyurethane-based binder cathode slurries, and aqueous cathode slurries employing polymer binders and alkali-salt polysaccharides, enhancing manufacturing efficiency and battery performance.

Figure 8: Capacity retention performances of cathodes with some non-PFAS binders patented by Northvolt, extracted from patents EP4492490 and WO2024/218134.

General Electrode Innovations: Northvolt has enhanced electrode technologies through electrode layer modifications and functional coatings such as insulating edge coatings to prevent inter-electrode shorts via ceramic-polymer binders at foil edges, fluorescently tagged binders enabling visualization of binder distribution, and patterned active-material regions forming built-in identification barcodes for automated tracking. Additionally, Northvolt has patented tab-less electrode connection and advanced edge preparation methods further enhancing electrode integration and reliability.

Battery Cells: Improved Architecture & Safety Features

Northvolt’s patent portfolio reveals a wide array of innovations covering multiple aspects of battery cell design and manufacturing.

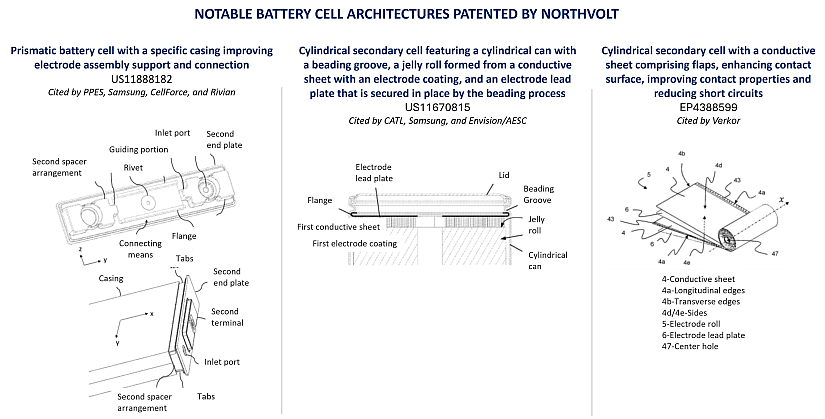

Several patents cover innovations on cell casing and assembly methods as well as electrode assembly with optimized current collector, morphology and electrode tab design. Several of these patents attracted strong attention from established battery manufacturers and car manufacturers. US11888182, covering a prismatic battery cell with a specific casing improving electrode assembly support and connection, is cited by PPES, Samsung, CellForce, and Rivian. WO2023/021182, cited by GD and LG Energy Solution, details a cylindrical secondary battery cell featuring a conductive sheet with strategically formed notches that enhance structural integrity and facilitate terminal connections. US11670815, attracting citations from CATL, Samsung, and Envision/AESC, involves a cylindrical secondary cell featuring a cylindrical can with a beading groove, a jelly roll formed from a conductive sheet with an electrode coating, and an electrode lead plate that is secured in place by the beading process. US20240283111, referenced by PPES, covers a cylindrical secondary cell featuring a cylindrical can with a blunted terminal through-hole design that enhances electrical isolation and reduces the risk of damage to the isolating part during manufacturing and use. US20240297417, cited by Samsung, covers an electrode assembly featuring positive and negative electrode plates with a coated active material portion and a non-coated portion and a separator containing a coating layer with organic and inorganic particles. US20240204373, cited by Microsoft, covers a cylindrical secondary cell with a terminal surface with different roughness

Figure 9: Notable battery cell architectures patented by Northvolt, extracted from patents US11888182, US11670815, and EP4388599.

Safety is a clear priority, with built-in features like fuses, pressure-relief elements, breakable components, sealants between electrodes, insulating layers, and strategic spacing elements designed to mitigate failure risks. Two of these patents have been noticed by other battery manufacturers. US20240162474, cited by Envision/AESC, covers a cylindrical secondary cell with integrated terminal and venting mechanism. EP4388599, cited by Verkor, covers a cylindrical secondary cell with a conductive sheet comprising flaps, enhancing contact surface, improving contact properties and reducing short circuits.

Northvolt’s patents also feature electrolyte formulations containing additives like LiBOB and LiDFPFSI, coupled with the use of separators made of inorganic/polymer compositions and high-energy chemistries such as high-Ni NMC, Si/SiOx-based anodes, and low-Co NMC variants, addressing market demand for higher energy density and reduced cobalt content. Another patented aspect is battery cells manufacturing processes such as shaping electrode tabs and alignment of electrode stacks.

Pack-Level Engineering: Modules, Thermal Management & BMS

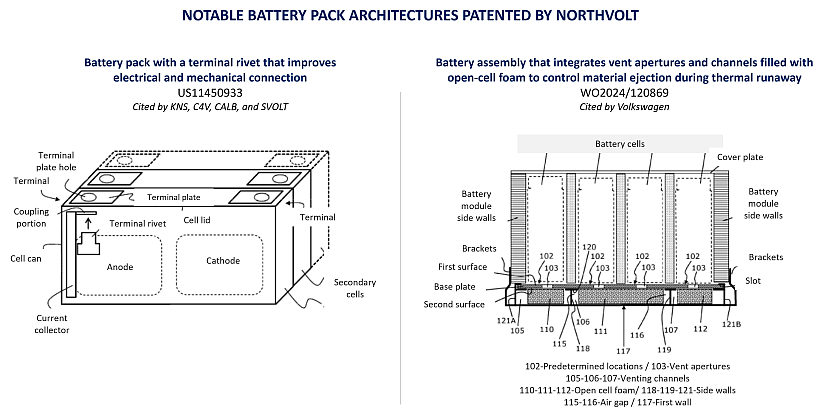

Northvolt’s portfolio extends beyond individual cells to include comprehensive technologies for battery packs and modules. These innovations encompass mechanical assemblies of cells and modules featuring various contacting and connectivity methods, optimized cell arrangements, and integrated venting, cooling, and thermal management systems. Many designs also incorporate embedded sensors to monitor key parameters. Among these patents, US11450933, covering a terminal rivet that improves electrical and mechanical connection, has drawn citations from companies like KNS, C4V, CALB, and SVOLT.

Figure 10: Notable battery pack architectures patented by Northvolt, extracted from patents US11450933 and WO2024/120869.

The patent portfolio highlights protection devices such as integrated fuses to safeguard against electrical faults, as well as robust module support structures and packaging solutions that enhance durability. Critical aspects like state-of-charge (SOC) and state-of-health (SOH) monitoring are also addressed, reflecting Northvolt’s emphasis on intelligent battery management. Among these patents, WO2024/120869, cited by Volkswagen, covers a battery assembly that integrates vent apertures and channels filled with open-cell foam to control material ejection during thermal runaway.

Additionally, patents held by Northvolt Systems cover inventions at the battery pack and module level, focusing on thermal management and cooling, electrical connections and interfaces, battery management systems (BMS), and safety mechanisms including pyrotechnic fuse protection, diagnostics, and fault detection. Two patents on connectors previously held by Northvolt have already been transferred to Scania Industrial, a company formed following Scania’s acquisition of parts of Northvolt Systems. Other IP assets held by Northvolt Systems may also be acquired by Scania to further build out this new entity’s patent portfolio.

Recycling Technologies: From Deep Discharge to Material Recovery

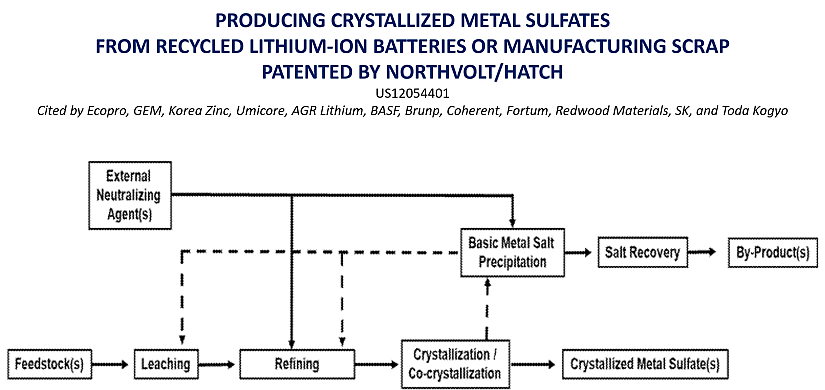

Northvolt’s patent portfolio demonstrates a robust focus on recycling technologies that span multiple stages of the battery materials recovery process. This includes methods for over-discharging and deep discharge of cells to safely prepare them for dismantling, recovering organic electrolytes using melt-crystallization techniques, and mechanical size-reduction approaches to concentrate active materials. Further innovations cover acid leaching processes, sulfate crystallization to produce battery-grade metal sulfates, phosphate-based methods for removing impurities such as aluminum and iron, and multi-stage precipitation techniques for fluoride removal from acidic leachates.

Among these, the most cited family was co-filed with Hatch in 2020 (US12054401). It details processes for producing crystallized metal sulfates from recycled lithium-ion batteries or manufacturing scrap. It has attracted citations from major players like Ecopro, GEM, Korea Zinc, Umicore, AGR Lithium, BASF, Brunp, Coherent, Fortum, Redwood Materials, SK, and Toda Kogyo.

Figure 11: Producing crystallized metal sulfates from recycled Li-ion battery or manufacturing scrap patented by Northvolt, extracted from patent US12054401.

US11509000 is another significant patent, which describes a process using phosphoric acid to precipitate and remove aluminum and iron impurities from leachates, enabling further recovery of NMC metals and lithium. This patent has been cited by companies such as Asaka Riken, Eneos, Eramet, Korea Zinc, LG Chem/LGES, Mitsubishi Materials, Redivivus, Rivian, and WaterCycle Technology.

EP3967661, cited by Umicore, Glencore, Korea Zinc, and Solvay/Syensqo, covers processes for preparing battery-grade metal sulfate solutions from used cathode plates. Additionally, US20250002340, cited by Mitsubishi Materials, outlines a multi-stage process for fluoride removal from recycling leachates.

Auxiliary Components: Connections, Housings & Sensors

Northvolt’s patents on other battery components include cell interconnections for precise electrical monitoring of individual cells, structural assemblies to solve how to organize and secure cells into larger modules or packs like thermal-aware positioning and spacer-aided modules, and housing solutions with slot-foam venting and top-lid modules for safe gas release. The portfolio also covers sensor integration for in-situ diagnostics, mechanical handling equipment, connectors, and EV board platform concepts, reflecting a holistic approach to battery design.

Manufacturing & Quality Control Systems

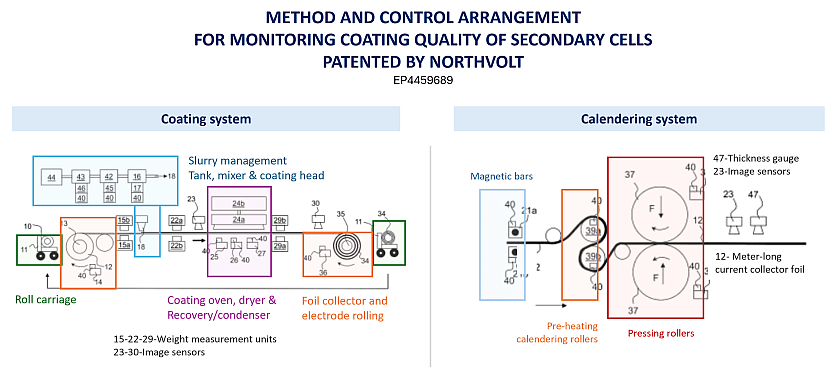

Northvolt’s patent portfolio also encompasses manufacturing and quality control technologies aimed at improving battery production efficiency and reliability, underlining Northvolt’s commitment to robust manufacturing and stringent quality assurance. Innovations include gas analysis systems during cell formation and methods to visualize binder distribution using organic fluorescent tags. Other patents cover specialized manufacturing equipment such as two-piece saggar trays, devices for applying insulating layers on electrode edges, precision electrode alignment tools, slot-die coating controls, and advanced drying chamber assemblies for battery electrodes.

Figure 12: Method and control arrangement for monitoring coating quality of secondary cells patented by Northvolt, extracted from patent EP4459689.

Quality monitoring technologies feature in-line CT-based cell inspections, coating quality checks, electrolyte impurity measurements, and roll-to-roll systems to detect electrode defects. The portfolio also highlights mass-scale battery health evaluation methods, walk-in chambers for accelerated testing, and systems for cell assembly incorporating heated films.

Cuberg Acquisition: Pioneering Lithium-Metal Anode Technologies

Acquired by Northvolt in 2021, Cuberg continues to operate under its own name, with most of its patents published after 2023, underscoring a fresh wave of innovation focused on lithium metal battery technology.

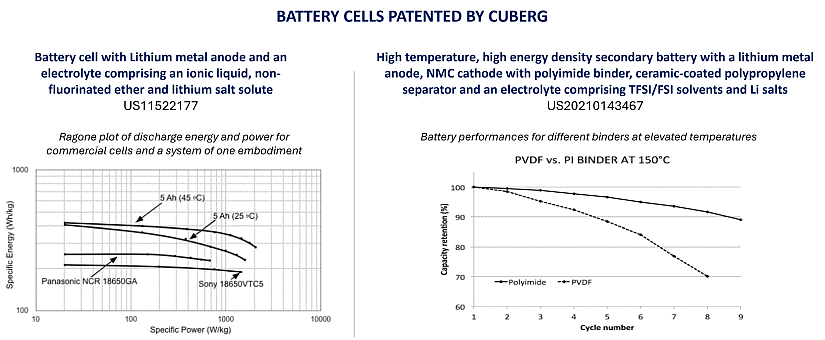

Cuberg holds four patent families centered on lithium metal anodes with specialized protection layers. The company filed ten patent families targeting battery cells featuring lithium metal anodes. These inventions address critical aspects such as optimizing reactivity, ionic conductivity, and high-temperature stability through innovations like high-porosity separators, single-crystal NMC cathodes, ionic liquid electrolyte formulations, metallized polymer current collectors, methods for restoring cell capacity, and pressure-managed battery assemblies.

A standout is patent family US11777087 (filed in 2019), covers rechargeable cells with lithium metal anodes on metallized plastic films combined with ionic liquid electrolytes. It has been notably cited by industry leaders such as ATL, LGES, Toyota, 3DOM, Arkema, EVE Energy, GM, GS Yuasa, Li-Metal Corp, Panasonic/Sanyo, and Aramco. Another key patent, US20210143467, describes systems for stable high-temperature lithium batteries using ionic liquid electrolytes and polyimide-binder cathodes, cited by CETC, Customcells, Gotion, Toyota, and Wayne State University.

Figure 13: Battery cells patented by Cuberg, extracted from patents US11522177 and US20210143467.

Additionally, Cuberg’s portfolio includes nine patent families on battery packs, covering advanced system management and modeling using physical models and neural networks, innovative cell and module designs tailored for pouch cells and aircraft applications, and safety solutions that manage lithium metal battery risks

Altris Collaboration: Emerging Sodium-Ion Battery Innovations

Northvolt’s collaboration with Altris has resulted in seven patent families focused on sodium-ion (Na-ion) battery technologies, all of which are still pending. There is a very high probability that Altris will ultimately acquire Northvolt’s share in these innovations.

The joint patents comprehensively cover multiple process steps for manufacturing anode-separator-cathode assemblies using Prussian blue analogues (PBA) as the cathode active material. Key innovations include:

- compositions of slurry and dry electrode coating for sodium-ion battery electrodes (EP4513579)

- process for coating and drying PBA-based cathodes (WO2025/109072)

- reducing residual water in PBA cathode layers to < 99 ppm (WO2025/109118)

- cut-and-calender workflow aligned with coating axis (WO2025/133146)

- laser cutting of coated Al sheets into electrode shapes (WO2025/099257)

- direct deposition of cellulose-based separator onto electrode (EP4539188)

- terminating drying of anode–cathode–cellulose assembly based on separator color measurement (WO2025/109042)

What Will Become of Northvolt’s Once-Promising IP assets?

For now, Northvolt’s extensive patent portfolio remains under the management of the trustee overseeing the bankruptcy process. In the coming months, several likely scenarios could unfold for these IP assets.

The patents co-assigned with other companies, such as those with Altris, will very likely be fully acquired by the respective co-assignees to consolidate ownership. Similarly, patents originally held by Northvolt Systems might be reassigned to the new entity Scania Industrial soon, depending on agreements finalized during its acquisition.

In the case of Cuberg, Lyten has already acquired the material assets in the US along with a production facility in Poland. Given that Lyten develops Li-S and Li-ion batteries featuring lithium metal electrodes, it could be motivated to strengthen its portfolio by acquiring Cuberg’s patents aligned with these themes.

The remaining patents could attract interest from a broad range of companies seeking to reinforce their own portfolios, especially those citing Northvolt’s patents. This would be a strategic move for firms wanting to secure freedom-to-operate or expand into advanced battery technologies.

Lastly, Northvolt’s intellectual property might even underpin a phoenix-like revival, as seen in the industry with examples such as Oxis Energy transforming into OxLid Energy (now acquired by Gelion), Lionano SE into Factorial Energy or Envia’s transition to Zenlabs (renamed Ionblox). Such a scenario could see Northvolt’s core technologies reborn under a new brand, continuing to drive innovation in the battery sector.

Press contact

contact@knowmade.fr

Le Drakkar, 2405 route des Dolines, 06560 Valbonne Sophia Antipolis, France

www.knowmade.com

About the author

Fleur Thissandier, PhD, works at KnowMade as Senior Analyst in the field of Materials Chemistry and Energy storage. She holds a PhD in Materials Chemistry and Electrochemistry from CEA/INAC, (Grenoble, France), and a Chemistry Engineering Degree from the Superior National School of Chemistry (ENSCM Montpellier, France). Fleur previously worked in battery industry as R&D Engineer.

About KnowMade

KnowMade is a technology intelligence and IP strategy consulting company specialized in analyzing patents and scientific publications. The company helps innovative companies, investors, and R&D organizations to understand the competitive landscape, follow technological evolutions, reduce uncertainties, and identify opportunities and risks in terms of technology and intellectual property.

KnowMade’s analysts combine their strong technology expertise and in-depth knowledge of patents with powerful analytics tools and methodologies to turn patent information and scientific literature into actionable insights, providing high added value reports for decision makers working in R&D, innovation strategy, intellectual property, and marketing. Our experts provide prior art search, patent landscape analysis, freedom-to-operate analysis, IP due diligence, and monitoring services.

KnowMade has a solid expertise in Compound Semiconductors, Power Electronics, Batteries, RF Technologies & Wireless Communications, Solid-State Lighting & Display, Photonics, Memories, MEMS & Sensors, Semiconductor Packaging, Medical Devices, Medical Imaging, Microfluidics, Biotechnology, Pharmaceutics, and Agri-Food.